The use of crawler PKT 10 - 60 allows you to speed up and significantly increase productivity, increase the duration of the X-ray tube and reduce the number of staff.

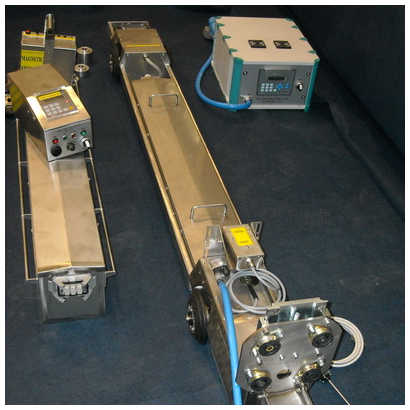

Radiographic crawlers PKT 10–60 are intended for pan-control of the quality of welded joints of pipelines with a diameter of 250–1500 mm. Crawlers are supplied with X-ray tubes (COMET, Balteau, ICM, Syntez etc.) for 200, 225, 300 kV.

AG operation is synchronized with the warning unit. He gives the sound or visual signs during the implementation of a given program to the Crawler. And the electromagnetic control system, without the use of isotopes, eliminates harm to the environment and the operator.

Features

- the radio return system will help return the crawler to its original position in case of failure of the electronics;

- infrared sensors eliminate the possibility of a crawler falling out of a pipe.

Equipment:

- Standard 19 A / h battery pack

- Control block

- Geiger Receiver / Magnetic

- Magnetic transmitter

- Auto centering wheels

- Expansion shafts for 10 "

- Spacers for diameters from 14 "to 24"

- Spacers for diameters greater than 24 "

- Component for dimers over 24 "

- Multi-channel charger 10 channels

- Stainless steel chassis CRAWLER 10 "-60" complete with electrical wiring

- 120V electric motor with shafts

Data sheet:

- designed for X-ray inspection of ring butt welded joints from 10 "to 60"

- Weight (kg. 104 with a 19Ah battery)

- length without x-ray tube: 1,900 cm.

- adapts to all types of x-ray tubes

- kv pitch change: 1kv

- movement speed: 14 m / min

- positioning accuracy: ± 5 mm

- maximum lifting angle in optimal condition: 27 ° (45%)

- dual control and monitoring system from outside the pipeline: with isotope or electromagnetic system

- The ability to also increase the exposure time with a tracked device inside the pipe (STM system)

- motion control system with a stop in the presence of obstacles and return

- Water alarm