In the AGFA NDT-S Eco developing machine, a cascade fixation system is used, due to which the amount of silver in water is 15 to 25 times lower than in a conventional washing machine.

The principle of cascade fixation is very simple in its essence: the exposed film is first processed in the developer, and then washed in the intermediate rinse tank. The intermediate rinsing system prevents the transfer of the developer to the fixative tanks and thus prevents the appearance of defects from the developer on the film.

Then the film is fixed in the first fixing tank and rinsed in the second. Since the replenishment with fixative is made in the second fixative tank, the concentration of silver in it remains very low; Consequently, the transfer of silver to the wash tank is reduced to 40 mg / m2. In addition, the exact replenishment of fixatives in such a system implies a low consumption of chemical reagents.

AGFA NDT-S Eco can be operated in a 5- or 8-minute cycle. In both cases, the capacity of NDT-S Eco is sufficient to satisfy consumers with high performance requirements.

The AGFA NDT-S Eco processing machine is equipped with triple drain valves, which allows for easy draining of photoreactive chemicals and cleaning chemicals to the appropriate tank.

The pallet for receiving the film in the machine AGFA NDT-S Eco can easily be adapted to work with format films of welding formats (from 6 × 12 cm and above), and roll films up to 5 m in length. The processed film will always be collected on a pallet accordingly.

| Processing programs | |||||||

| Time of processing | 12 | 10 | 8 | 6 | 5 | 2.5 | 1.5 |

| Standard drying installation (increase) | 1 | 1 | 1 | 2 | 11 | 14 | 16 |

| Setting Drying Limits (Increasing) | 1-8 | 1-8 | 1-10 | 1-12 | 1-16 | 1-20 | 1-20 |

| Standard developer temperature | 25 | 26 | 28 | 30 | 31 | 36 | 36 |

| Standard fixer temperature | 28 | 28 | 28 | 30 | 31 | 36 | 36 |

|

The number of refreshing solution (ml / m2) |

|||||||

| Developer | 900 | 900 | 900 | 900 | 550 | 600 | 600 |

| Fixer | 1200 | 1200 | 1200 | 1200 | 600 | 800 | 800 |

|

Water (l / m2) |

13 | 13 | 13 | 13 | 13 | 10 | 10 |

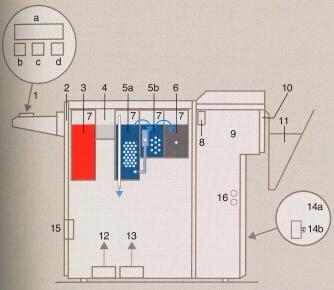

Scheme:

1. Feed tray:

a) LCD display;

b) program selection;

c) setting the increase;

d) setting reduction.

2. Scan the film surface.

3. Developer tank.

4. Flush tank.

5a. Tank for fixer F1.

5b. Tank for fixer F2.

6. Final flush tank.

7. Removable grill.

8. Transport rollers.

9. Infrared dryer.

10. The release of the film.

11. Receiving pallet.

12. Pump replenishment developer.

13. Pump replenishment fixer.

14. On / off switch

15. Triple drain valves.

16. Device for overheating protection of the developer and fixer.